Nickel Coating Diamond Powder are generally divided into two different produce coating types:

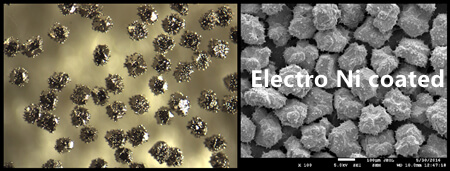

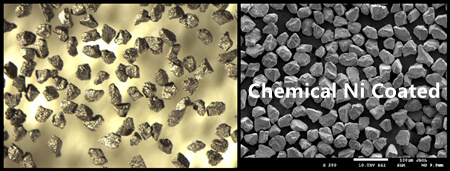

Electroplating and Chemical plating

|

Coating type |

Weight increase |

Available size |

|

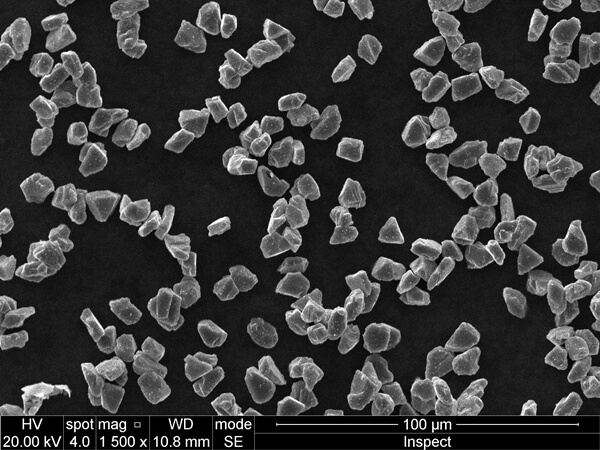

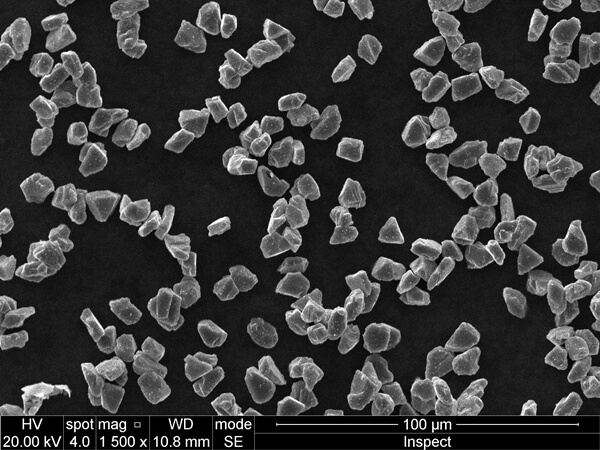

Cluster Nickel Coating |

30%-60% |

20/25-5-10μ |

|

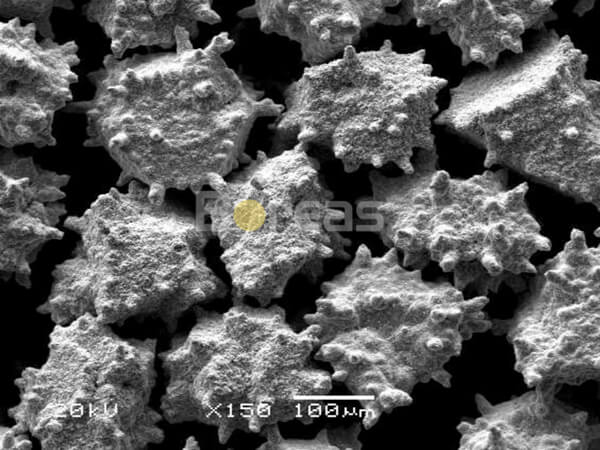

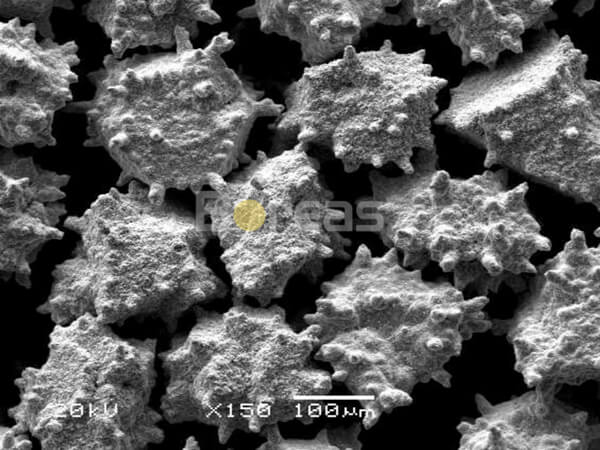

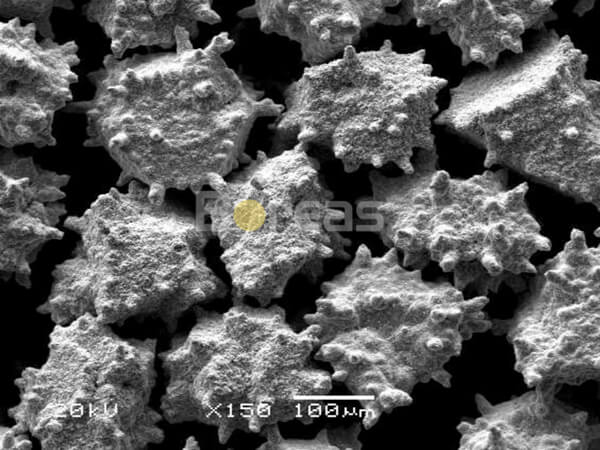

Spiky Nickel Coating |

56%-60% |

20/25-270/325 |

|

Double-layer Coating (Ti,Ni) |

30%-60% |

20/25-15-25μ |

Special requirements can be customized.

Advantages:

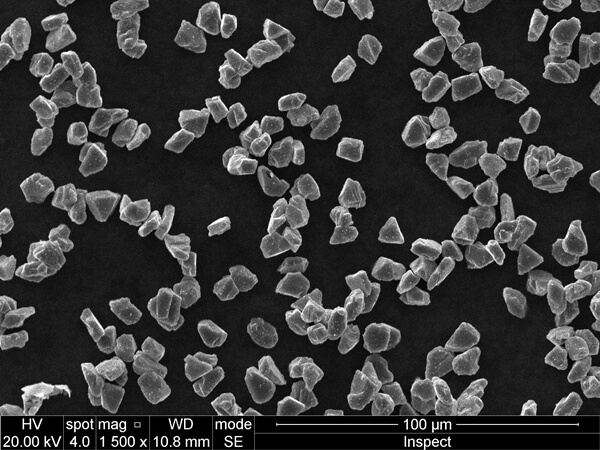

*Rough and spiny surface, improve the retention between diamond and bond;

*Avoid the diamond peeling off early, extend the service life of diamond tools;

*Increase bond retention, Minimize the instance of crystal pull-out;

*Prevent diamond surface from chemical etching and oxidation.

Application field:

*Chemical nickel coating mainly for resin bond products;

*Electro nickel coating mainly for resin bond products;

*Copper coating mainly for metal bond products;

*Ti coating mainly for metal and ceramic bond products.