【BRM-PCD】Micron Diamond Powder for PCD Synthesis Description

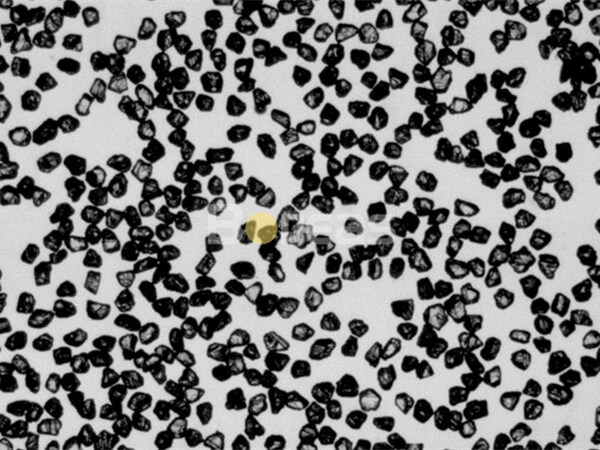

PCD is composed of micron-sized diamond powder and binder ( cobalt ) sintered at high temperature and high pressure. In the sintering process, high strength diamond bonding is formed between diamond powder particles. The combination of diamond powder particles has the advantages of high wear resistance, hardness and thermal conductivity and good machinability. It is suitable for drawing iron, stainless steel, copper, aluminum, nickel and other non-ferrous metal alloy wires, so it has been widely used in drawing industry. At present, most of the diamond drawing dies use PCD core.

When the sintering temperature is 1550 °C, the synthesis pressure is 5.7 ± 0.1GPa and the sintering time is 180s, the synthesis experiment of micron-sized polycrystalline diamond was carried out by using the domestic six-sided top press. The effects of different particle sizes ( 10μm, 5μm, 2μm, 1μm ) of diamond powder on the microstructure and properties of synthesized PCD were studied. SME, XRD and Raman were used to characterize the microstructure of the synthesized PCD samples, and their wear resistance and heat resistance were tested. The results showed that D-D bond was formed in the PCD samples, and graphite existed in the samples when the particle size of diamond raw material was 2 μm. With the decrease of the particle size of diamond raw material, the diffusion of Co element is more uniform, and the wear ratio of the synthesized PCD sample is smaller, and the heat resistance temperature is lower.

| 0-0.25 |

0-0.5 |

0-1 |

1-2 |

2-4 |

3-6 |

4-8 |

| ✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

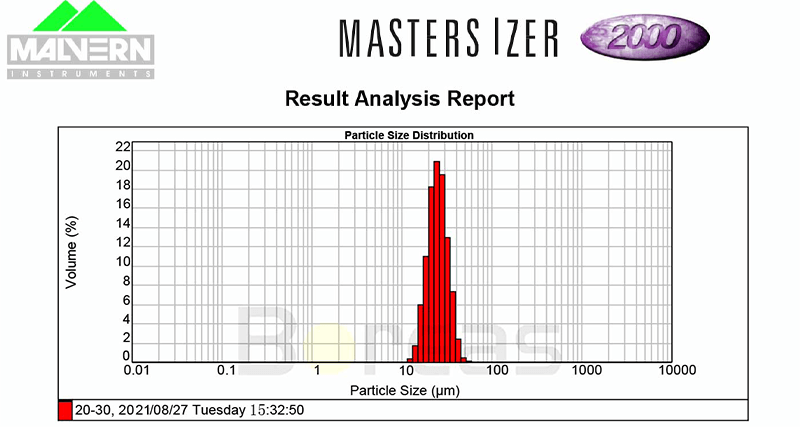

| 5-10 |

6-12 |

7-14 |

8-12 |

8-16 |

10-20 |

15-25 |

| ✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

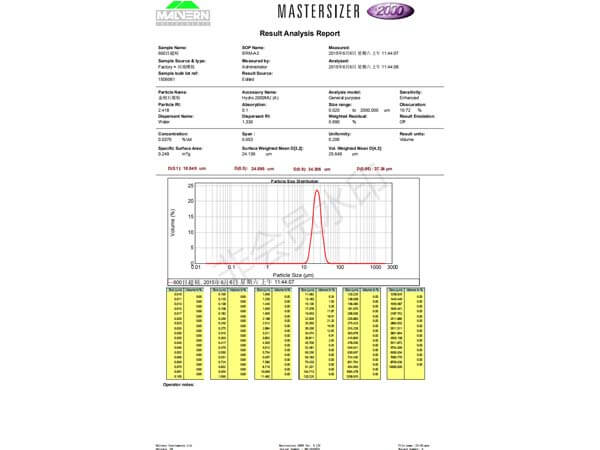

| 20-30 |

22-36 |

30-40 |

20-40 |

36-54 |

40-50 |

40-60 |

| ✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

DiamondPowder Catalog.pdf

DiamondPowder Catalog.pdf