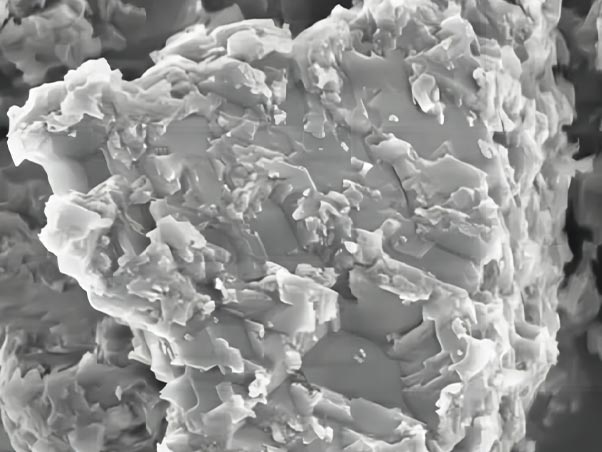

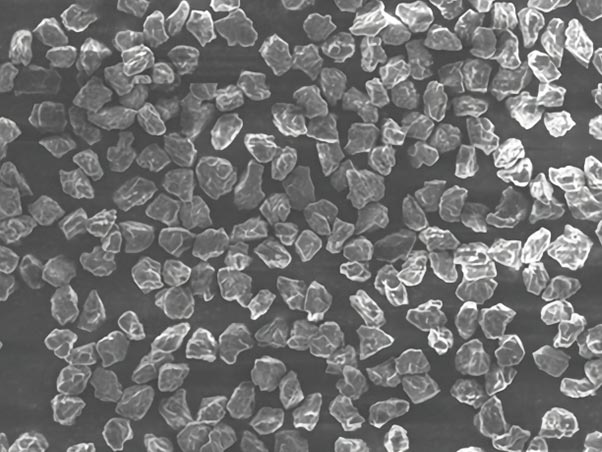

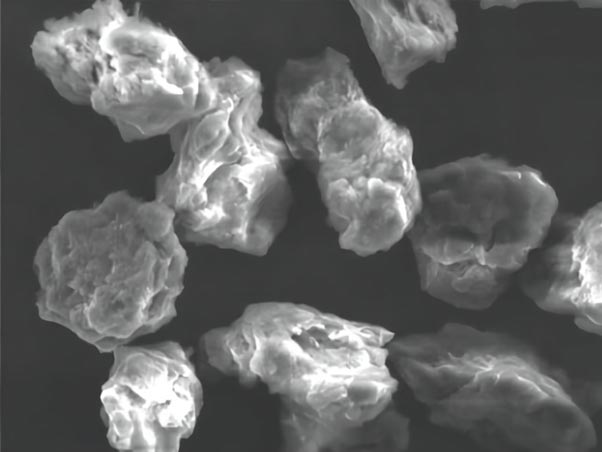

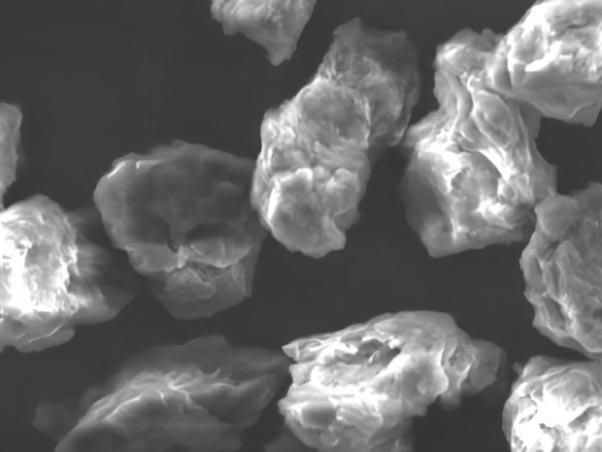

Polycrystalline Diamond Powder Description

Features :

◆ Higher toughness and better self�sharpening properties compared with monocrystalline diamond.

◆ Higher removal rate, less scratches, more consistent polishing performance compared with monocrystalline diamond.

◆ High wear resistance and long service life.Application:

1. Surface polishing of various ceramics;

2. Applications in the field of high-end semiconductor materials;

3. Used as encapsulation material and magnetic recording system for IT products;

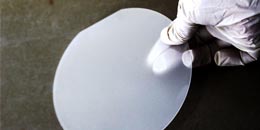

4. Lapping and polishing of semiconductor wafers such as SiC and sapphire wafers;

5. Used as a lubricant or oil additive, it can improve the operational performance of industrial machinery and vehicles, reduce faults and extend service life.

| Specification |

D10(μm) |

D50(μm) |

D90(μm) |

| BRM-PD 0-1 |

≥0.05 |

0.40-0.60 |

≤1.00 |

| BRM-PD 0-2 |

≥0.05 |

0.90-1.10 |

≤2.00 |

| BRM-PD 1-3 |

≥1.00 |

1.90-2.10 |

≤3.00 |

| BRM-PD 2-4 |

≥2.00 |

2.90-3.10 |

≤4.00 |

| BRM-PD 3-6 |

≥3.00 |

4.40-4.60 |

≤6.00 |

| BRM-PD 4-8 |

≥4.00 |

5.90-6.10 |

≤8.00 |

| BRM-PD 2-5 |

≥2.00 |

7.40-7.60 |

≤10.00 |

| BRM-PD 5-10 |

≥5.00 |

3.40-3.60 |

≤5.00 |

| BRM-PD 6-12 |

≥6.00 |

8.90-9.10 |

≤12.00 |

Polycrystalline diamond powder.pdf

Polycrystalline diamond powder.pdf