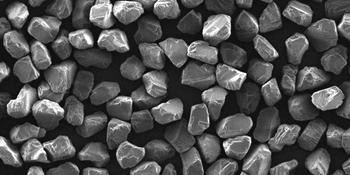

Sharp synthetic diamond abrasive Description

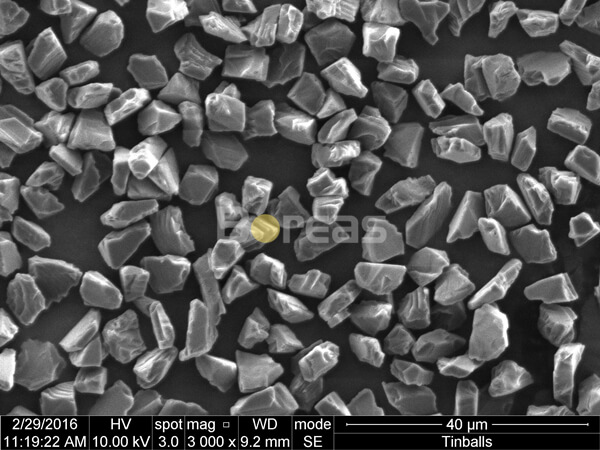

【BRM-B】Sharpened Series Micron Diamond Powder

Applications: Resin bond, Vitrified bond, Metal bond, Electroplated diamond tools diamond compound, diamond slurry for grinding & polishing stone, glass, ceramic, dental materials, hard metal materials, etc.

Avaliable Sizes: 0-0.25 to 40-60

Classification: BRM-B1, BRM-B2, BRM-B3

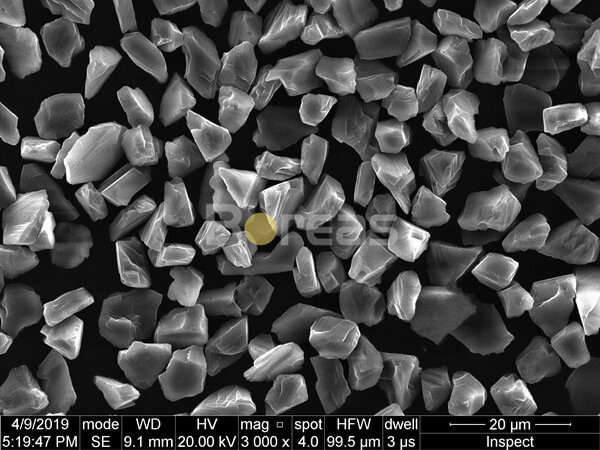

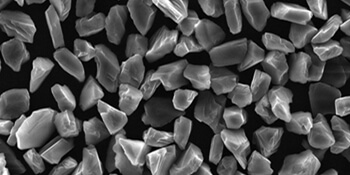

【BRM-GC】High Purity Micron Diamond Powder

Application: Recommended diamond tools for high-quality PCD / PDC synthesis, single-layer bonding ( electroplating and brazing systems ), metal bonding and hybrid bonding.

Avaliable Sizes: 0-0.25 to 40-60

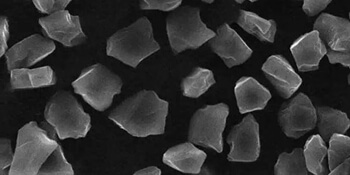

【BRM-GM】Green&Yellow Micron Diamond

Application: Suitable for resin bond grinding tools, used for processing hard alloy, glass, ceremics, stone grinding and polishing.

Avaliable Sizes: 0-0.25 to 40-60

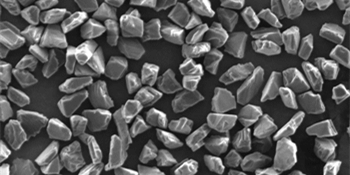

【BRM-V】Diamond Powder For Vitrified Bond Tools

Application: Customized for Vitrified bond diamond tools.

Avaliable Sizes: 0-0.25 to 40-60

【BRM-WSD】Micron Diamond Powder for Diamond Wire

Application: Make diamond wire for dicing & slicing monocrystalline silicon, polycrystalline silicon, sapphire, LCD, magnetic materials, semiconductor materials, also used for other premium diamond grinding & polishing tools.

Available Coatings: Chemical Ni coating, Electroplated Ni coating, Ti-Ni composite coating, customized coatings are also available. (Nickel coating can greatly enhance the retention between diamond particles and core wire.)

DiamondPowder Catalog.pdf

DiamondPowder Catalog.pdf