Metal Bond Micron Diamond Description

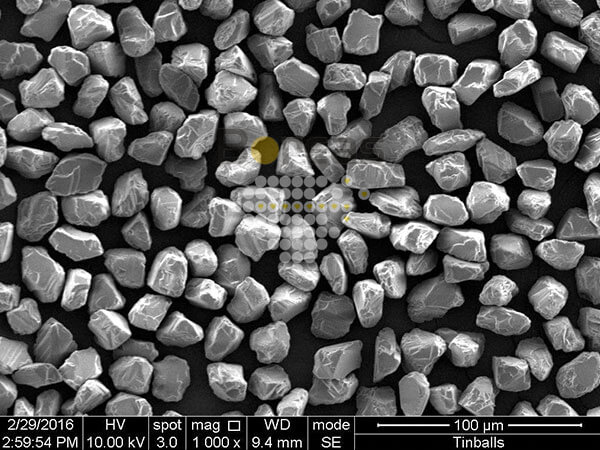

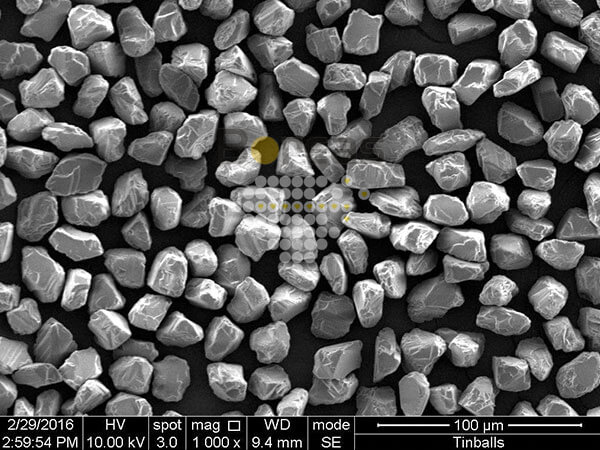

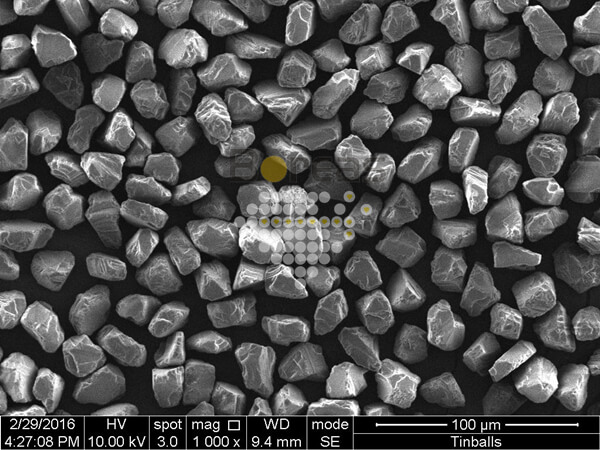

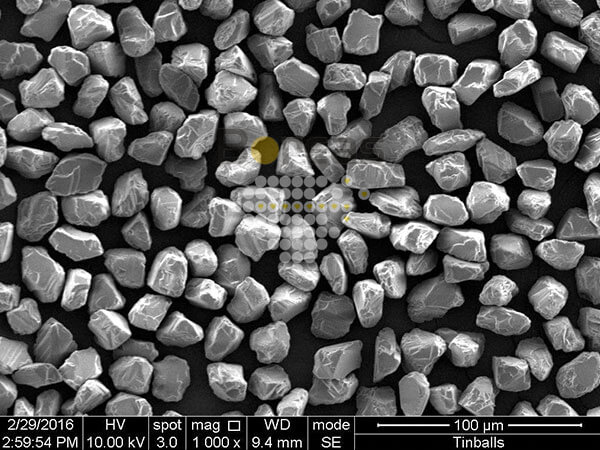

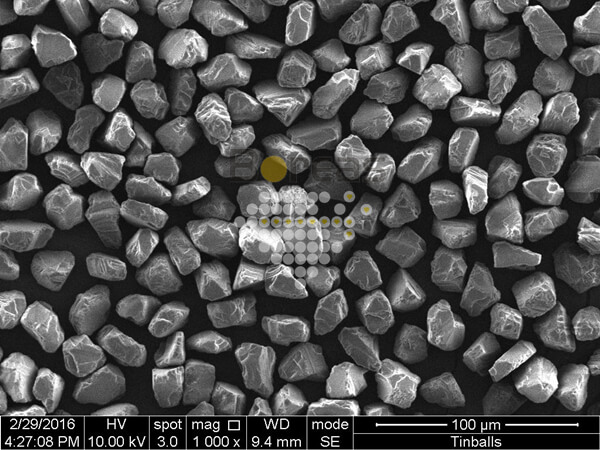

BRM-A / Blocky Series Micron Diamond Powder:

Characteristics:Produced with premium grade MBD diamond as raw materials, high strength and grinding force, uniform and near-spherical particle shape, concentrated particle size distribution(PSD), low impurity, good dispersion and wear resistance.

Available Size: 0-0.25 to 40-60

Classifications: BRM-A1, BRM-A2, BRM-A3

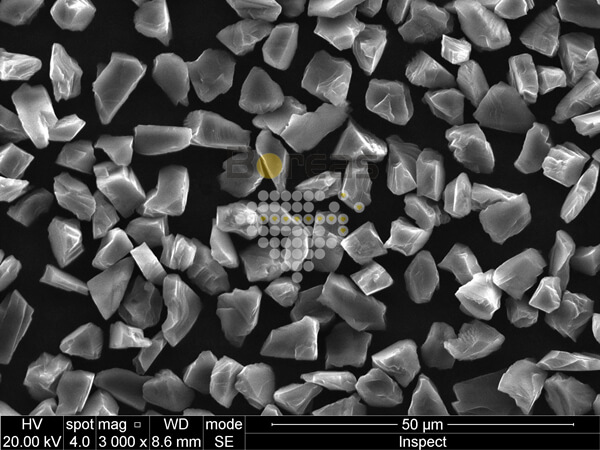

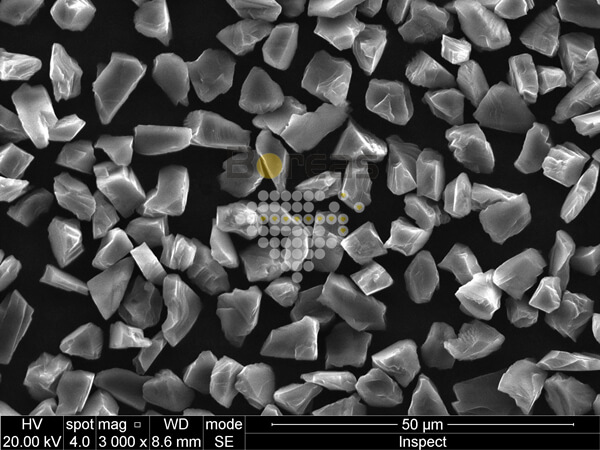

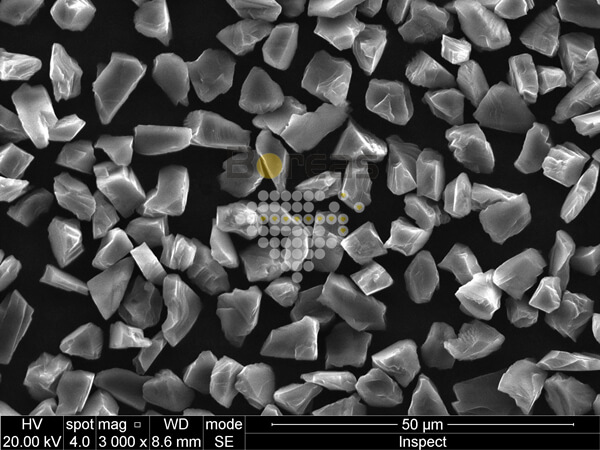

BRM-B / Sharpened Series Micron Diamond Powder:

Characteristics:With premium grade MBD diamond as raw materials, produced by special crush, reshape, sizing and post processing technique.

Relatively concentrated particle size distribution(PSD), high strength, low impurity, sharpened particle shape, good workpiece surface roughness.

Available Size: 0-0.25 to 40-60

Classifications: BRM-B1, BRM-B2, BRM-B3

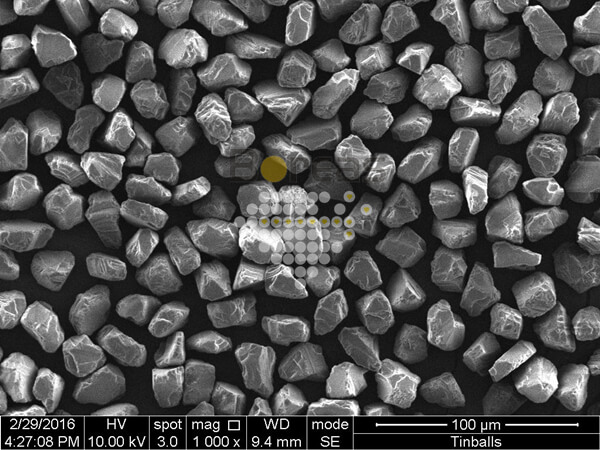

BRM-HS / High Strength Micron Diamond Powder:

Characteristics:Produced with highest strength MBD diamond as raw materials. Regular blocky crystal shape, good therm stability, longer tool life.

Recommanded for fine ceramics, glass, sapphire, aerospace materials, 3C products, geological drilling, and other industries with special processing requirements.

Available Size: 0-0.25 to 40-60

BRM-HP / High Purity Micron Diamond Powder:

Characteristics:Made of highest grade MBD diamond, extremely low intrinsic impurity and special acid & alkali treatment to ensure the total impurity content at PPM level, very good fluidity & dispersity & therm stability.

Recommended for superior PCD/PDC synthesis, single layer bond(Electroplated & Brazed system), metal bond, hybrid bond diamond tools

Available Size: 0-0.25 to 40-60

BRM-WSD / For Diamond Wire:

Characteristics:High strength, regular crystal shape, highly concentrated particle size distribution & effective particles, strictly control of rod-like and flaky shape particle, low impurity, high cutting efficiency of good sharpness, prominent dispersity and wear resistance. Make diamond wire for dicing & slicing monocrystalline silicon, polycrystalline silicon, sapphire, LCD, magnetic materials, semiconductor materials, also used for other premium diamond grinding & polishing tools

Available Coatings: Chemical Ni coating, Electroplated Ni coating, Ti-Ni composite coating, customized coatings are also available.

(Nickel coating can greatly enhance the retention between diamond particles and core wire. )

| Micron Size |

Medium D50μm |

BRM-A1 |

BRM-B1 |

BRM-WSD |

BRM-PCD |

BRM-GQ |

BRM-GC |

| 0-0.25 |

0.11-0.20 |

√ |

√ |

√ |

√ |

√ |

√ |

| 0-0.5 |

0.20-0.30 |

√ |

√ |

√ |

√ |

√ |

√ |

| 0-1 |

0.6-0.8 |

√ |

√ |

√ |

√ |

√ |

√ |

| 0-2 |

0.9-1.1 |

√ |

√ |

√ |

√ |

√ |

√ |

| 1-2 |

1.1-1.3 |

√ |

√ |

√ |

√ |

√ |

√ |

| 1-3 |

1.6-1.8 |

√ |

√ |

√ |

√ |

√ |

√ |

| 2-3 |

1.9-2.1 |

√ |

√ |

√ |

√ |

√ |

√ |

| 2-4- |

2.2-2.6 |

√ |

√ |

√ |

√ |

√ |

√ |

| 2-4 |

2.6-3.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 2-5 |

3.1-3.4 |

√ |

√ |

√ |

√ |

√ |

√ |

| 3-6 |

3.5-4.2 |

√ |

√ |

√ |

√ |

√ |

√ |

| 4-6 |

4.4-5.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 4-8 |

5.0-6.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 4-9 |

6.1-6.5 |

√ |

√ |

√ |

√ |

√ |

√ |

| 5-10 |

6.5-7.3 |

√ |

√ |

√ |

√ |

√ |

√ |

| 6-12 |

7.3-8.3 |

√ |

√ |

√ |

√ |

√ |

√ |

| 7-14 |

9.1-10.5 |

√ |

√ |

√ |

√ |

√ |

√ |

| 8-12 |

8.3-9.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 8-16 |

10.0-12.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 10-20 |

12.5-15.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 12-22 |

15.0-17.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 15-25 |

18.0-20.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 20-30 |

20.0-23.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 22-36 |

23.0-26.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 30-40 |

29.0-32.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 20-40 |

26.0-29.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 35-45 |

32.0-36.0 |

√ |

√ |

√ |

√ |

√ |

√ |

| 36-54 |

37.0-43.0 |

√ |

√ |

√ |

√ |

√ |

√ |

DiamondPowder Catalog.pdf

DiamondPowder Catalog.pdf

DiamondPowder Catalog.pdf

DiamondPowder Catalog.pdf